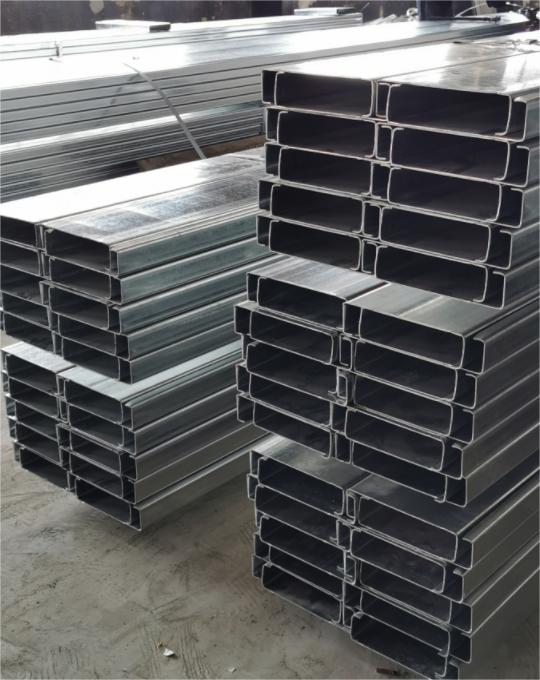

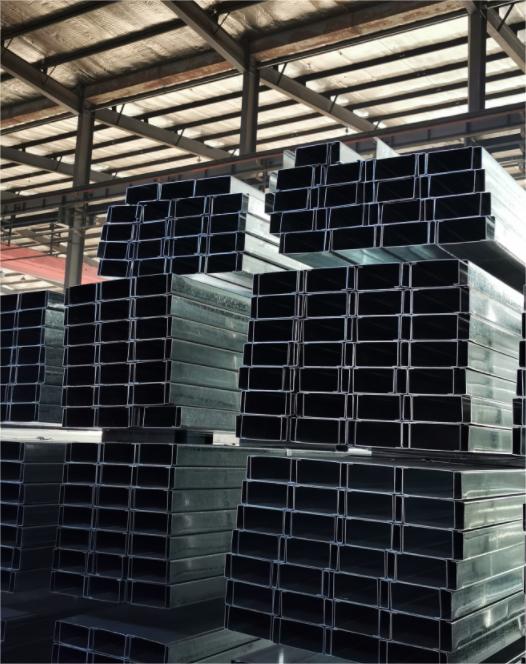

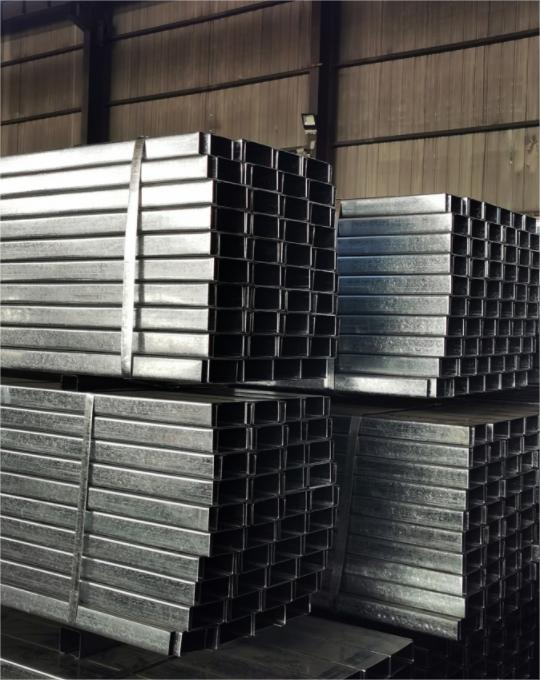

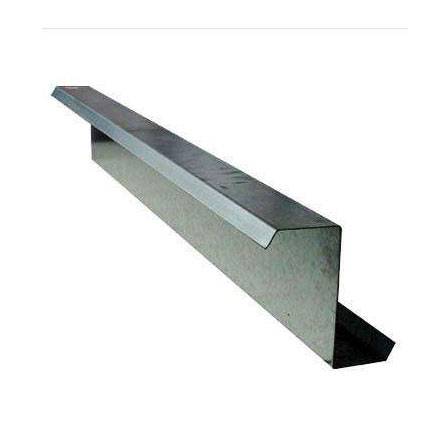

Steel Fabricated CZU

Yiziphi izinqubo zokukhiqizaInsimbi Eyakheke Ebandayo?

Inqubo yokukhiqiza yezigayo ezigoqiwe ezibandayo ilawula ngokuyinhloko ukulungiswa kwe-billet, ukucotshwa, ukugoqa okubandayo, ukudonsa kanye nokuqedwa.

Ukulungiswa okungenalutho kudinga ukwakheka kwamakhemikhali, ububanzi kanye nezikali zokujiya (umehluko wamaphuzu amathathu kanye nomehluko wemigqa efanayo), futhi ukugoba kwesikela kufanele kuhlangabezane nezidingo, futhi ingaphezulu kufanele libe bushelelezi futhi lingabi nemifantu, ukugoqa, i-delamination, ama-pores, okungewona ukufakwa kwe-metallic, njll.

Insimbi ye-strip kufanele iqondiswe futhi i-butt ishiselwe ngaphambi kokukhetha ukuze kukhethwe okulandelanayo.Inhloso eyinhloko ye-pickling ukuqeda isikali se-iron oxide.Phakathi nenqubo yokukhetha, ukugxila kanye nokushisa kwesisombululo se-asidi kanye nokuqukethwe kukasawoti oyi-ferrous kusixazululo se-asidi kufanele kulawulwe.

Ukuze ulawule ukujiya kanye nokuma kwepuleti, ukuncishiswa, isivinini, ukushuba kanye nokuma kwe-roll kufanele kulungiswe.Ugqinsi kulawulwa ikakhulukazi yi-AGC, futhi ukwakheka kwepuleti kulawulwa ngokuyinhloko ngokulungisa iphrofayili ye-roll (umqhele we-roll kanye nendlela yesinxephezelo somqhele), njenge-HC, CVC, njll.

I-Annealing ihlukaniswe yaba i-annealing emaphakathi kanye ne-fining annealing.Ukukhishwa kwesikhungo kuwukuqeda ukuqina komsebenzi, futhi ukukhishwa kwemikhiqizo ukuthola isakhiwo nomsebenzi odingekayo.Izithando zomlilo zihlanganisa izindawo zokushisa ezilandelanayo kanye neziqhumane zohlobo lwensimbi.Inqubo yokuvala isithando somlilo sohlobo lwensimbi kufanele ilawule ingxenye yegesi evikelayo esithandweni, isikhathi sokushisa, nesikhathi sokupholisa;inqubo yokuthungatha yesithando somlilo esilandelanayo kufanele ilawule izinga lokushisa, isivinini, isikhathi kanye nomkhathi ngokuya ngejiko lokudonsa.Lawula ukushuba kwesithando somlilo ukuze uqinisekise ukuma kwepuleti, futhi ulawule umqhele weroli lomlilo ukuze ugweme ukuchezuka komugqa.

Ukuqeda kuhlanganisa ukwenza isicaba, ukusika, ukugcoba amafutha nokupakisha.I-flatness ingathuthukisa ukuma kwepuleti, ihlanze indawo futhi ithole imisebenzi edingekayo.Inqubo yokwenza isicaba kufanele ilawule ukunwetshwa komugqa, futhi ukugunda kufanele kulawule isikali nekhwalithi yendawo ephezulu, uwoyela kufanele ufane, futhi ukupakishwa kufanele kuhlangabezane nezidingo ezishiwo, okulungele ukugcinwa, ukuthutha kanye nokulethwa.

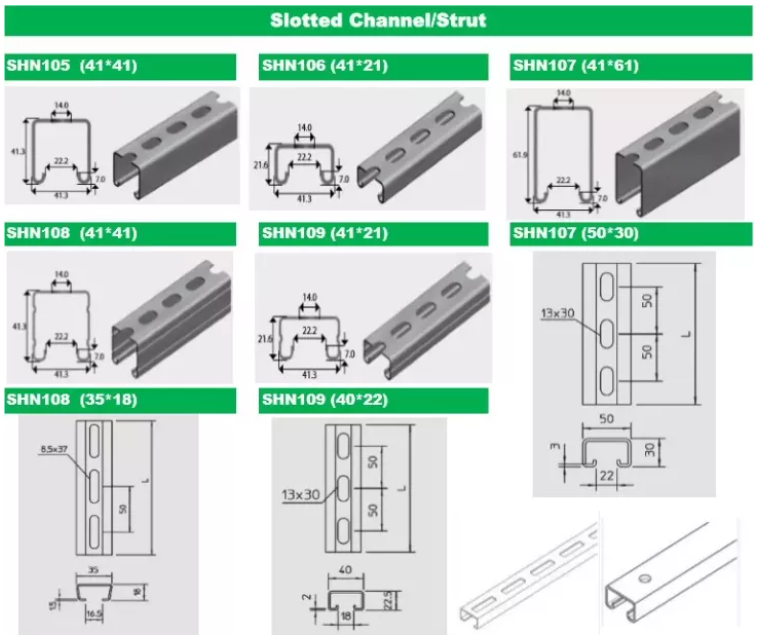

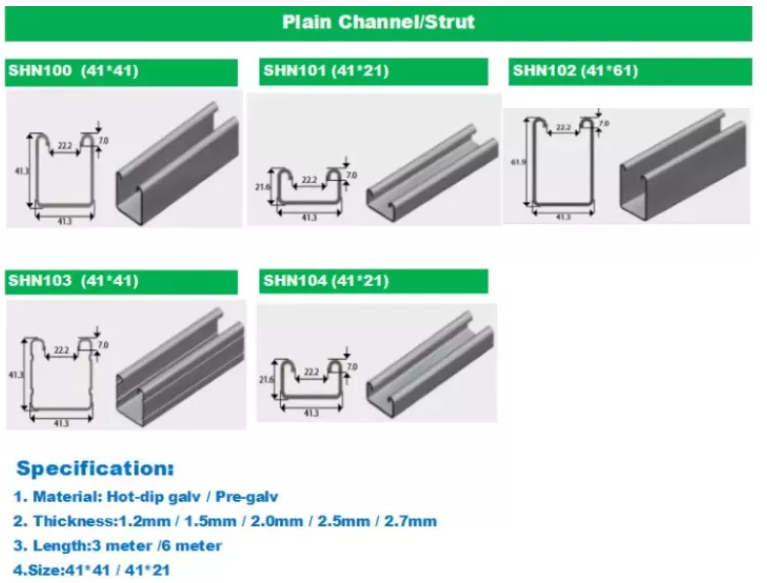

| CHA. | Usayizi | Ubukhulu | Uhlobo | Ubuso Ukwelashwa | ||

| mm | Intshi | Ubukhulu | Isilinganiso | |||

| A | 21*10 | 13/16*13/32" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| B | 21*21 | 13/16*13/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| C | 41*21 | 1-5/8*13/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| D | 41*22 | 1-5/8*7/8" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| E | 41*25 | 1-5/8*1" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| F | 41*41 | 1-5/8*1-5/8" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| G | 41*62 | 1-5/8*27/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

| H | 41*82 | 1-5/8*3-1/4" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | Ifakwe, Iqinile | HDG,PG,PC |

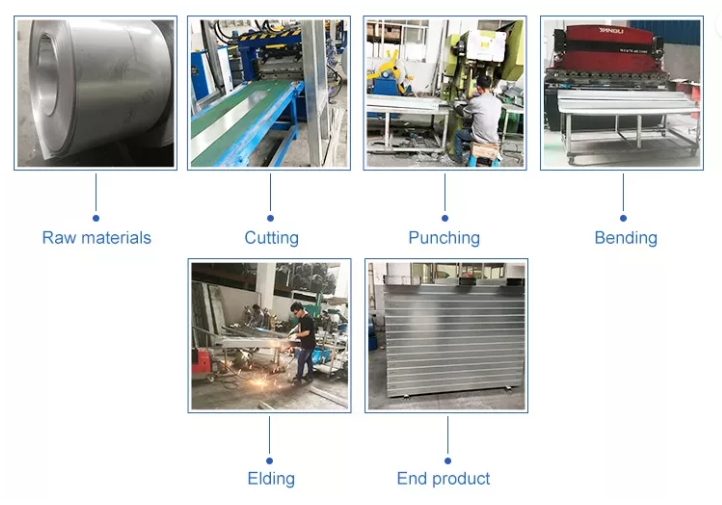

Konkeiphrofayili yensimbi eyakhiwe ebandayoabunjwe ngokucutshungulwa okuzenzakalelayo umshini wokwenza i-C-steel, othi ngosayizi abanikiwe we-C-steel, ongaqedela ngokuzenzakalelayo inqubo yokwakheka kwe-C-steel.

Imbobo Eyisiyingi Yokuphakela-Ukucaba-Ukwakha-Ukulinganisa-Ukuqondanisa-Ubude-Ukubhoboza Imbobo Eyindilinga ye-tie-bar -Ukubhoboza Imbobo Eyisiyingi Yokuxhuma Imbobo Ukusika Imbobo