Umkhiqizi we-dip dip galvanizing (ishubhu lensimbi).

Ukuphakela → ukucosha, ukuwasha → isincibilikisi → ukomisa → idiphu elishisayo ukuvuthela → ukuphephuka ngaphakathi nangaphandle → ilebula egoqayo, ukumaka → ukudlula → ukuhlola → ukupakisha.

Isisebenzi esilayishayo sizobheka isimo sezinto ezibonakalayo:

1. Ubuso obungaphandle bepayipi yensimbi akufanele bunamathele ngamafutha (ikakhulukazi amabala amafutha afana nopende wokuxuba amafutha e-asphalt), ngaphandle kwalokho inani elikhulu lemikhiqizo engafaneleki lizobangelwa.

2. Ipayipi yensimbi kufanele iqondiswe ngemva kokukhiqizwa ukuze kuqedwe ukucindezeleka kwangaphakathi kwepayipi yensimbi.

3, i-steel tube surface corrosion engalingani ayikwazi ukuvuthwa, ngaphandle kwalokho kuzochithwa okuningi kwe-hydrochloric acid.

- Akukho ukugoba okwenziwayo okuvunyelwe ohlelweni lokuthuthwa kwamapayipi ensimbi.

5. Ngamapayipi ensimbi anamapayipi ashisayo-dip, akuvunyelwe ukunamathisela amamaki ezindongeni zangaphakathi nangaphandle zamapayipi ensimbi ukuze kugwenywe ukuvuza kwe-plating.

1. Ukukha ipayipi lensimbi:

1) Izisebenzi eziqoayo kufanele zigqoke izinto zokuvikela abasebenzi ngaphambi komsebenzi, zihlole ngokucophelela ukuthi asikho yini indawo yokusebenza engenazithiyo nokuthi isihlilingi siphelele, bese umsebenzi wenziwe ngemva kokuqinisekiswa.

2) I-Hydrochloric acid isetshenziswa kakhulu ekukhetheni, futhi i-hydrochloric acid ilungiswa ngamanzi.Okuqukethwe kwe-hydrochloric acid yi-18-20%, okufanele kakhulu.

3) Qonda ukugcwala kwe-asidi, izinga lokushisa kanye nethoni yepayipi lokukha ethangini ngaphambi kokukhetha.

4) Lapho uphakamisa ipayipi, izihlilingi ezimbili kufanele zibe cishe ngamamitha angu-1.3 ukusuka ekugcineni, ukuze ugweme ukugoba ipayipi lensimbi futhi kubangele ukuvuza epayipini likathayela;Lapho wehla ngeshubhu uya ethangini le-asidi, ishubhu lensimbi kufanele kutshekiswe ngo-15°, ukuze kwehlise indawo emile yeshubhu kuqala, ukuze kuvinjelwe isifutho se-asidi ekulimazeni abantu.

5) Ukucoshwa ngakunye kwepayipi lensimbi kufanele kube nesisindo samathani ama-2 ~ 5 kanye nesikhathi semizuzu emi-5 ukuya kweyi-15.

6) Ishubhu lensimbi kufanele lidlidlize njalo ngesikhathi sokukhetha.Enqubweni yokudlidliza, ishubhu lensimbi kufanele libekwe phezu kwetshe elivundlile lethangi le-asidi, futhi indwayimane ngakolunye uhlangothi kufanele iqalwe ngokuphindaphindiwe izikhathi ezi-3, bese i-sling ngakolunye uhlangothi kufanele iqalwe futhi izikhathi ezi-3. , bese iphakanyiswa ngemva kokuphindaphindwa kabili;I-engeli yokuphakama kokudlidliza ayinkulu kuno-15°.

7) Uma ithangi le-asidi lishisa, lungisa ipayipi le-steam ngokuqinile ngaphambi kokuvula i-valve ye-steam.

8) Uma i-crane crane ingena noma iphuma ethangini le-asidi, akufanele ishayisane nodonga lwethangi ukuvimbela ukulimala ethangini le-asidi.

9) Izimbangela eziyinhloko zokuvuthwa kwamashubhu ensimbi:

(1) ipayipi lensimbi kufanele lihlolwe ngokuqinile lapho liphakela, futhi ipayipi lensimbi elingafanelekile akufanele lifakwe ekuqoqweni.

(2) Ipayipi lensimbi alisebenzi ngokucophelela lapho lidlidliza.

(3) Isikhathi sokukhetha esinganele kanye nokuqukethwe kwe-hydrochloric acid.

10) Izimbangela eziyinhloko ze-steel tube pickling:

(1) Okuqukethwe kwe-hydroelectric acid ngokweqile.

(2) Isikhathi sokukha side kakhulu.

11) Ngemva kokukhetha, hlola ukuthi indawo yangaphandle yepayipi yensimbi ibushelelezi, ukuthi kukhona isikali sensimbi esisele kanye nokuthi ingaphezulu lepayipi lensimbi lingcoliswe isikali samafutha.

2. Ukugeza amanzi kwamashubhu ensimbi:

1) Ukugeza amanzi kwepayipi lensimbi kufanele kwenziwe ethangini lamanzi ahlanzekile agelezayo.Cwilisa wonke amapayipi ensimbi emanzini lapho uwasha, phumuza isihlilingi sokucosha bese usuka futhi uhambe izikhathi ezintathu kuya kwezine.

2) Ngemva kokugeza, amanzi angaphakathi kwepayipi lensimbi kufanele alawulwe futhi aphathwe nge-solvent ngokushesha ngangokunokwenzeka ukuvimbela i-oxidation ye-tube yensimbi.

I-3) Okuqukethwe kwensimbi nosawoti emanzini okuhlanza akumele kudlule izinga, futhi ngeke kube khona okunye okuhlukile.Kumelwe kugcinwe kuhlanzekile futhi kusobala.

4) Lapho uhlanza ipayipi, akuvunyelwe ngokuphelele ukuthi ama-opharetha anyathele phezu kwe- pickling tank ukuze agweme ukushelela noma ukuwela ethangini ukuze alimaze abantu.1.Lapho ithubhu lensimbi lingena ethangini le-solvent, khulula isihlilingi ukuze ishubhu lensimbi licwiliswe ku-solvent ngokuphelele.Ingaphezulu leshubhu lensimbi alivunyelwe ukuveza indawo encibilikayo. Kuze kube yilapho zombili iziphetho zeshubhu lensimbi zingenawo amabhamuza, uhlangothi olulodwa lweshubhu lensimbi lizophakanyiswa phezulu naphansi ukuze lidlidlizele, futhi ishubhu lensimbi kufanele liphakanyiselwe lawula i-solvent ehlanzekile bese ungena ebhentshini lokumisa.

2. I-Angle etshekile yepayipi yensimbi akufanele ibe mkhulu kune-15 ° enkambisweni yokwelashwa kwe-solvent.

3, ishubhu lensimbi ngesikhathi sokucwiliswa kwe-solvent semizuzwana engama-60 ~ 120, ukucwiliswa kweshubhu lokubuya 3 ~ 5 imizuzu, ukucwiliswa kweshubhu lokubuya 5 ~ 10 imizuzu.

4. Izinga lokushisa elincibilikayo: Gcina i-solvent ihlanzekile ekamelweni lokushisa.

5. Ngemva kokwelashwa kwe-solvent, unganamatheli kokunye ukungcola, ungamanzi, yibeke etafuleni lokumisa ukuze ulinganise;Abantu abavunyelwe ukunyathela ipayipi lensimbi elibekwe ebhentshini elomile.Uma kufanele inyathelwe, zombili izinyawo kufanele zigcotshwe nge-ammonium chloride ngaphambi kokusebenza epayipini.1.Ngemva kokwelashwa okuncibilikisiwe okufanelekayo, beka ishubhu lensimbi endaweni yokomisa neyokwamukela, bese ubeka ishubhu lensimbi ohlangothini olungaphambili lwebhodwe le-zinc kanye nohlangothi olungaphambili lwerola kazibuthe lesibili ukuze libe isikwele ku-Engeli engakwesokudla; ngemuva noma iqondiswe futhi ibekwe endaweni yokubeka yokwamukela.

2. Umsebenzi oyinhloko wokomisa i-KANG ukomisa amanzi ebusweni be-tube yensimbi.Ngakolunye uhlangothi, ukuphakamisa izinga lokushisa kwe-tube yensimbi ngokwayo, ukuvimbela ukuchithwa kwe-zinc ekulimazeni abantu, futhi kungathathi amandla okushisa ebhodweni le-zinc, ukuze kusheshiswe ukwakheka kwe-zinc-ferroalloy layer.

3. Izinga lokushisa le- kang 80℃ ~ 180℃, futhi isikhathi sokumisa sepayipi lensimbi imizuzu engu-3 ~ 7.Izinga lokushisa lokumisa lingalawulwa ngokuvumelana nokucaciswa nokuqina kodonga lwepayipi lensimbi.Izomisa kufanele zihlole izinga lokumisa lepayipi lensimbi nganoma yisiphi isikhathi ukuvimbela ukuntuleka kwesikhathi ekulinyazweni kwe-zinc liquid splash zinc;Lapho womisa, yenza ungeqi izinga lokushisa, ukuvimbela i-coke yokubhaka encibilikisiwe.Ipayipi lensimbi elidiphu elishisayo lamukela isimiso somshini sokudayela ngaphakathi, ukucindezela phansi, ukusonga, ukukhipha kanye nokuphakamisa indlela yokucwilisa ngokugcwele ipayipi lensimbi eyisi-othomathikhi ukuze liqedelwe. inqubo ye-hot-dip galvanizing.

1. Ukulawulwa kwamapharamitha wenqubo: Izinga lokushisa lesisombululo se-zinc kufanele lilawulwe phakathi kuka-440-460 ℃;Isikhathi sokucwilisa i-Zinc kufanele silawulwe phakathi kwamasekhondi angu-30-60; Okuqukethwe kwe-Aluminium (Izinga loketshezi lwe-Zinc eliqukethe i-aluminium 0.01-0.02%)

2. I-Zinc ingot kufanele ibe yi-zN0-3 ingot ye-zinc enezinga likazwelonke.

3. Gcina futhi ulawule ukusebenza okuthembekile kwesikulufu sokuvula nokucindezela kanye nokukhipha idivayisi yokuphakamisa njalo, qinisa ukugcotshwa kwesilinda, lungisa ukuphakama kanye ne-Angle yomsabalalisi wepayipi elikhiqiza kahle, futhi ulungise imishini ibe yisimo esifanele.

4. Misa iswishi ye-proximity ngokunembile; ulayini we-thermocouple kanye nemitha kuzosetshenziswa kumodeli efanayo, ngaphandle kwalokho, iphutha lokushisa likhulu, umkhono wokuvikela we-thermocouple, ngokuvamile uhlola futhi ushintshe.

5. Umqhubi wesiteshi sokusebenza uzolungisa mathupha isivinini ngokuvumelana nesimo sokusebenza kwemishini phambi kwesithando somlilo kanye nomyalo wokuthinta ukuvimbela ukunamathela kwepayipi.

6. Shisisa ngaphambili amathuluzi asetshenziswa izisebenzi zesithando somlilo ngaphambi kokuwasebenzisa ukuze uvimbele ukuchitheka nokulimala kwe-zinc; Hlola njalo ukuthi ipayipi lensimbi liyawela yini ebhodweni, uma likhona, ukuze liphume ngesikhathi; ukuqinisekisa ukuphepha kwemishini.

7. Uma wengeza i-zinc ebhodweni le-zinc, ama-zinc ingots kufanele ashiswe kuqala.Ungalokothi uvumele izinyanda ze-zinc zengezwe, zingabi ngaphezu kwezingcezu ezinhlanu ze-zinc ngesikhathi.

I-8, lapho i-zinc encibilika kufanele ishiswe kancane kancane, ungashisi umlilo, ngaphandle kwalokho izolimaza impilo yebhodwe likathayela, futhi kune-volatilization eningi ye-zinc. ”.Enqubweni yokuncibilikisa i-zinc, uma i-zinc inezinga lokushisa eliphezulu akumele ithinte ibhulokhi ye-zinc ngesandla, ukuze ugweme ukusha, kufanele isebenzise amathuluzi afanele ukuyithinta.

9, ukusula njalo i-zinc liquid ebusweni bomlotha we-zinc.Lapho ukhuhla umlotha kufanele ube ngobumnene phezu koketshezi lwe-zinc nge-scraping plate scraping swab, awukwazi ukugubha kakhulu, funa umlotha we-zinc uphakanyiswe, ipuleti lokukhuhla akufanele libe. ukucwilisa i-zinc noma ngaphandle kweshubhu lapho ishubhu lensimbi lithintana, ukuze lingagingqiki phezu kwesenzakalo sezingozi zomuntu siqu noma izingozi zemishini.

10. Amabhulokhi e-zinc angaphansi komhlaba phambi kwesithando somlilo, i-zinc ephukile, i-zinc ekhishwa lapho i-galvanizing, kanye nepayipi lensimbi ye-zinc eligeleza ngaphandle kufanele litholakale noma nini ukuze kuncishiswe ukulahlekelwa ukushisa kwebhodwe le-zinc.

11. Uma i-aluminium ingots yengezwa ebusweni be-zinc ewuketshezi, kufanele ihanjiswe izikhathi eziningana ngaphambi nangemuva kokuqinisekisa okuqukethwe kwe-aluminium efanayo ebusweni be-zinc ewuketshezi.

12. Ukuze kube lula ukugcwala kwamanzi nokukhipha i-zinc, amathani angama-20 omthofu kufanele afakwe ngaphakathi ebhodweni le-zinc.

I-13, ama-slag dregs wokushisa ama-dregs, i-zinc slag ukuze ihlukaniswe isitoreji samabhulokhi amakhulu namancane, izinga lokushisa le-dregs kufanele lilawulwe ku-455 ℃ ngaphezulu, umshini we-swing slag kumele usebenzise amathuluzi akhethekile, kude ne-zinc pot 1 imitha, izinyawo ukuma endaweni emise okwe-t.

I-14, idiphozi elishisayo lidinga inqubo yokuqinisa amandla kakhudlwana, ngakho-ke enqubweni yokukhiqiza yediphu elishisayo, kufanele yome isiteshi esigcwele, okungukuthi, ngenombolo yempande yesikhathi seyunithi noma i-tonnage ngaphezulu, izindleko ziphansi, futhi okuphambene nalokho ziphakeme.1.Ngemva kokuba ipayipi likathayela libekwe phambili, itafula le-roller kazibuthe lisetshenziselwa ukuholela ngaphandle kwepayipi likathayela, futhi ukuguqulwa komshini oholayo akusheshi kakhulu, ukuze i-zinc igeleze ihlanzekile ngaphambi kokuvunguza kwangaphakathi.

2. I-engeli yendandatho ephephezelayo yangaphandle kufanele ihambisane nerola kazibuthe ema-engeli angakwesokudla, futhi indawo eyilongitudinal kanye ne-transverse kufanele ibe iphozithivu ukuze kuqinisekiswe ukuthi ipayipi eliwuthayela lidlula phakathi kwendandatho yomoya.

3. Lapho ufaka i-roller kazibuthe, ama-roller kazibuthe amahlanu kufanele abe semugqeni ophakathi nendawo ukuze kuqinisekiswe ungqimba lwezinc olufana nolwepayipi elivuthelwe ngaphandle.

4. Ukuvuthela kwangaphandle kuzokwenziwa ngomoya ocindezelwe, okungcono ngaphezu kuka-70℃, ngaphansi kwengcindezi engu-0.2-0.4mpa.

5. Umfutho womoya uzolungiswa ngaphansi kwalezi zimo ezilandelayo:

(1) Ungqimba lwezinc endaweni engaphandle yepayipi likathayela likhulu kakhulu.

(2) Ingaphezulu le-zinc layer iba mnyama ngemva kokuvunguza kwangaphandle.

(3) Ngemva kokuvunguza kwangaphandle, ingaphezulu longqimba lwezinc linamathela kwezinye futhi kuhlulwe izinto ezingcolile.Ivolumu yomoya kufanele ilungiswe.

6. Faka esikhundleni indandatho yomoya yokucaciswa okufanayo ngokusho kokucaciswa kwepayipi lensimbi elinamandla.Iringi yomoya ayikwazi ukushintshwa ngenye imininingwane.

7. Akuvunyelwe ukudlula ipayipi eliphehliwe ngaphansi kwesimo somoya, ukuze kungabangela ukuvinjelwa kwembobo yomoya futhi kuthinte izinga lokushaywa kwangaphandle.

8. Ngaso sonke isikhathi hlola ukuthi ingaphakathi lendandatho ephephezelayo yangaphandle ihlanzekile yini, ingabe ikhona yini i-zinc elengayo, ukuthi ingaphandle lepayipi likathayela libushelelezi yini nokuthi kukhona yini ukuklwebheka; Ukuthi ingaphezulu lerola kazibuthe, iketango lixhunywe nezinc. , uma kukhona okuxhunywe ne-zinc ukuhlanza ngesikhathi.

9. Njengoba ingekho i-roller kazibuthe futhi ungqimba lwezinc aluqinile, indawo engaphezulu yengqimba ye-zinc ngokunokwenzeka kakhulu yokuklwejwa, ngakho ijubane lerola eliholayo kufanele lihambisane kahle nele-roller kazibuthe.1.Ipayipi elinothayela le-hot-dip lithunyelwa eceleni kwesiphephetha sangaphakathi ngesisetshenziswa esiholayo, futhi iswishi yokusondela isetshenziselwa ukuqedela ukunyakaza okuvundlile, cindezela phansi ukuvunguza kwangaphakathi, ukuphakamisa ikhanda lokucindezela, futhi ukuhambisa idiphu elishisayo libe ngamagalani. iphayiphi kusinki wokupholisa.

2. Ishubhu elivalwe ngokushisayo yilona okungenzeka kakhulu ukuklwebheka phezu kwetafula le-roller eliholayo.Isizathu esiyinhloko ukuthi i-zinc ayizange iqine ngokuphelele ngesikhathi sokusebenza kwe-tube.

3. Isitimu sisetshenziselwa ukuvuthela kwangaphakathi, futhi umfutho ovunguzayo wangaphakathi ngu-0.4-1.0mpa;Indawo engaphakathi yepayipi eliwuthayela kufanele bushelelezi.

4, ipayipi lashukumisa iketango ukuze alondoloze ethile etshekile Angle, ukuze inetha amanzi okupholisa.

5. Indawo yokusebenza yokuphefumula kwangaphakathi isendaweni engumqansa enendawo encane yokusebenza, ngakho-ke kufanele isetshenziswe ngokucophelela ukuze kuvinjwe ukulimala okushelelayo, ukuwa nokugoba; ukuze ugweme ukulimala.

6. Qaphela ukuthi izinyawo zakho zimi ziqinile futhi zikhona yini ezinye izithiyo ezikuvimbela ukuthi ungaweli kusinki;Kulula ukushiya iketango ligijima kusinki, ukuvikela ukulimala kwamashubhu endizayo.Incazelo: Lapho izingxenye zidinga ukugcinwa. futhi ithuthwe isikhathi eside, ukudlula kufanele kwenziwe phakathi kwezingxenye ukuvimbela ukugqwala ekugcinweni nasekuthuthweni kwenqubo.Imikhiqizo yokugqwala ivame ukubizwa ngokuthi ukugqwala okumhlophe.Izindlela ezivamile zokudlula zihlanganisa i-chromate ne-phosphate.

1. Indlela yokudlulisa: ipayipi elinothayela elishisayo lisetshenziselwa ukufafaza isixazululo se-passivation ngqo kumzila wezindiza, futhi isisombululo siyasulwa ebangeni lemitha elilodwa ukusuka endaweni yokufafaza ngommese wesitimu.Qaphela ukuthi ukhiphe isisombululo se-passivation.

2. Sula ngomoya ocindezelwe ukuze ukhiphe uketshezi ebusweni bepayipi lensimbi futhi wenze umfaniswano wokumboza.Ngokulungisa ingcindezi yokulungisa ukushuba kwengubo, abukho ubuhlalu obudlulele okufanele bufakwe ebusweni beshubhu ye-zinc. 1.I-Rolling mark ne-roller:

1) Uma umshini wokumaka usebenza, ungathinti i-roller yokumaka ngesandla sakho ukuze uvimbele ukucindezelwa kwesandla; Akuvunyelwe ukudlulisa ipayipi eliphindwe kabili emshinini wokumaka ukuze uvimbele ukulimala kwe-press roll.

I-2) Ngesikhathi sokusebenza kwepayipi elithathiwe etafuleni elidlulisayo, umshini wokumaka uzoshintsha inothi ngokuya ngemininingwane ehlukene, futhi ukuphakama kwesondo lokucindezela kuzolungiswa lapho imininingwane ishintshiwe, futhi uwoyela uzofakwa njalo.

3) Indandatho yerabha yomshini wokumaka kufanele ihlolwe njalo futhi ishintshwe ngesikhathi uma kukhona ukuqhekeka okutholakalayo.

I-4) Isondo lenjoloba lizocindezelwa emgqeni ophakathi we-tube yensimbi, futhi ama-bolts okulungisa angaphezulu naphansi ane-Angle yokucindezela okuhle azolungiswa.

5) Lapho uphrinta indandatho yelogo, abantu ababili kufanele bagingqike ngasikhathi sinye.Uyinki kufanele wengezwe njalo ukuze ugoqe ipayipi lensimbi ngokuzwa, kodwa uyinki akulula ukuba ube mningi kakhulu.

2. Ukupakisha:

I-1) I-baler ISEBENZISA igesi ye-compressor yomoya, futhi ingcindezi i-0.4-0.8mpa.Kunqatshelwe ukuthinta izingxenye ezihambayo ze-baler ngezandla zakho ukuze ugweme ukulimaza izandla zakho ngaphansi kwesimo sokusebenza se-baler.

2) Uma upakisha, qala ngokufaka amabhande ebhandeni lokupakisha, bese ufaka ibhande lokupakisha eduze kwepayipi lensimbi bese ufaka omunye umkhawulo emigqumeni.Bese ucindezela umshini wokupakisha ebhandeni lokupakisha bese uvula i-valve yomoya yomshini wokupakisha wokupakisha nokucindezela.Ingxenye ewugqinsi yebhande lokupakisha yi-1.0-1.2mm.Ibhande lokupakisha lidingeka ukuthi libe ngu-100mm ukusuka ekugcineni, libe ngu-300mm ukusuka engxenyeni yesibili, futhi libe ngu-400mm ukusuka ekugcineni kwebha yophawu oluluhlaza okwesibhakabhaka.

3) Khetha i-rack yokupakisha yokucaciswa okufanayo kwamapayipi othayela, faka amapayipi ama-galvanized abe yisimo se-hexagonal futhi wenze umkhawulo owodwa ulingane.

4) Uma ingaphandle lepayipi lensimbi elipakishiwe lidala ukungcola, lihlanze ngesihlabathi sikakotini esihlanzekile ngaphambi kokupakisha.Uma izimo zivuma, amanzi angaphakathi epayipini elincane kufanele alawulwe futhi ahlanzwe;Ungavumeli noma ubani ukuba anyathele ishubhu ngonyawo lwakhe, ukuze alondoloze ukubukeka kwekhwalithi yamashubhu anothayela.

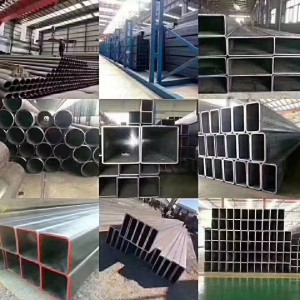

I-Tianjin Rainbow Steel Group ikhiqiza umkhiqizo wensimbi osezingeni eliphezulu eChina.

Umkhiqizo singawenza kanjena:

Ibanga Lomkhiqizo Wethu Oyinhloko:

1. Ipayipi Lensimbi(Isiyingi / Isikwele/ Okukhethekile/SSAW)

2. Ipayipi kagesi kagesi(EMT/IMC/RMC/BS4568-1970/BS31-1940)

3. Cold Formed Steel Isigaba(C /Z /U/M)

4. I-Angle yensimbi ne-Beam( V Angle Bar / H Beam / U Beam)

5. I-Scaffolding Prop yensimbi

6. Isakhiwo Sensimbi(Uhlaka luyasebenza)

7. Ukunemba Inqubo Ensimbi(ukusika, ukuqondisa, ukwenza isicaba, ukucindezela, ukugingqa okushisayo, ukugoqa okubandayo, ukugxiviza, ukubhola, ukushisela, njll. Ngokwemfuneko yekhasimende)

8. Umbhoshongo wensimbi

9. Isakhiwo Sokukhweza Solar

Inzuzo Yenkampani Yethu:

1.Inani:Inkampani yethu itholakala eTianjin China.Sekungamashumi eminyaka, i-Tianjin iyisikhungo semboni yensimbi kanye nesizinda esikhulu sokukhiqiza ipayipi lensimbi eChina.Uchungechunge lwezimboni lwensimbi nemikhiqizo yensimbi luphelile;Inempahla enkulu kanye nezinsiza zabasebenzi lapha.Ngakho-ke izinhlobo zamapayipi ensimbi ezenziwe lapha ziphelele kakhulu, ikhwalithi iphezulu kakhulu, intengo inenzuzo kakhulu.NJENGEnkampanini yeqembu, izimboni zethu ezine zingathola inani elincomekayo lezinto zokusetshenziswa ngenxa yokuthengwa kwenani elikhulu leqoqo elilodwa lezinto.Izintengo zemikhiqizo yokuthekelisa zonke ziyizintengo zeqembu le-intro, ngakho-ke sinenzuzo yenani kunabanye abathekelisi abazimele.

2.Ezokuthutha:Izigayo zethu ziqhele ngamakhilomitha angama-70 ukusuka echwebeni laseTianjin, okuyitheku elikhulu kunawo wonke enyakatho yeChina, elinemikhumbi ethunyelwa emachwebeni angaphezu kwama-300 emazweni ayi-170.Inkampani yethu Kuphela Ilula kakhulu futhi yonga kokubili isikhathi nezindleko zokuhamba.

3.Isevisi yokuma okukodwa:Njengenkampani yeqembu, sinezigayo ezine ezinendawo yokugcina impahla & yokucubungula yesimanje, singakuhlinzeka ngohlu olubanzi lwemikhiqizo yensimbi: okwakhiwa okugoqiwe okushisayo nokubanda, okuhlanganisa inhlobonhlobo yebha yomthengisi, imikhiqizo yesakhiwo neshubhu.Sinazo zonke izinto zensimbi zasekhaya, ezentengiselwano nezimboni kanye namasevisi ongase uwadinge.Ngakho-ke uma uthenga kithi, esingakunikeza isevisi yomkhiqizo wensimbi eyodwa-stop.Konga isikhathi sakho esiningi sokuthenga nezindleko zokuthola usizo.

4. Amandla omkhiqizo kanye nokulethwa:

Sinomthamo omkhulu wokukhiqiza, futhi sithekelisa ngaphezu kwamathani angama-3500 ngeviki (cishe iziqukathi ze-GP ezicishe zibe ngu-150 20), Singaletha izimpahla Zingakapheli izinsuku ezingama-20-30 ngemuva kokuthola idiphozithi ye-T/T noma i-L/C.Kuma-oda aphuthumayo akhethekile, singanciphisa isikhathi sokuhola sibe izinsuku eziyi-10.

5. Kwenziwe ngokuvumelana namazinga ahlukene, Hlangana namazinga ahlukene:

Njengoba imikhiqizo yethu ithunyelwe emazweni amaningi ahlukene nasezifundeni ezifana neYurophu, iMelika, i-Australia, i-Afrika, i-Asia njll. , imikhiqizo yethu ingahlangabezana nezidingo zamazinga ahlukene kazwelonke.Uma unezidingo ezikhethekile, vele usitshele, singakukhiqizela imikhiqizo eyenziwe ngokwezifiso, singagcini nje ngokuhlangabezana nezidingo zakho zekhwalithi, kodwa futhi sikusindise izindleko eziningi.

Abasebenzi bethu abanolwazi nabanolwazi bahlale bekulungele ukuphendula imibuzo yakho mayelana nemikhiqizo namasevisi ethu.

Izindleko zamasheya Tianjin Rainbow Steel Group Co., Ltd.

Ucingo: 0086-22-59591037

Ifeksi: 0086-22-59591027

Iselula: 0086-13163118004

I-imeyili:tina@rainbowsteel.cn

Wechat: 547126390

Iwebhu:www.rainbowsteel.cn

Iwebhu:www.tjrainbowsteel.com

Isikhathi sokuthumela: Aug-17-2020